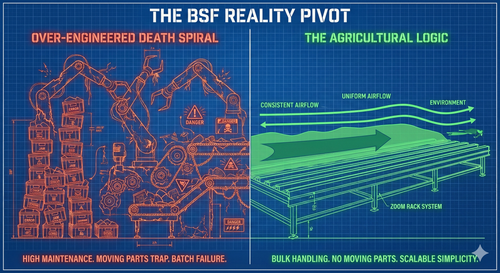

Most Black Soldier Fly (BSF) startups are currently trapped in a "high-tech" death spiral. They are building million-dollar "warehouses" when they should be building high-efficiency "farms."

In a recent session of the Black Soldier Fly Leaders podcast, Bob Holtermans, the "Flying Dutchman" and CEO of Insect Engineers, pulled back the curtain on why 2025 was a year of "bad news" stories—and how engineering simplicity is the only way to make the numbers work in 2026.

1. The Philosophical Shift: Warehouse Logic vs. Agricultural Logic

The industry standard has become the 60x40cm plastic crate. It looks great in a pitch deck—rows of neat boxes and robotic arms. But Bob Holtermans, drawing from 20 years in the mushroom industry, calls this out as a logistic warehouse solution, not a farming one.

The Problem with Crates:

- The Moving Parts Trap: Insects create a cocktail of heat, high humidity, and ammonia. If your system relies on robotic arms or sensors inside the rearing room, you are inviting a maintenance nightmare.

- The "Dead Space" Issue: To get proper airflow in a crate stack, you often have to leave massive gaps. Bob notes that farms pitching "20 crates high" usually end up at "12 crates high" just to keep the larvae from over-heating.

The "Zoom" Solution:

Bob’s Zoom Rack system uses aluminum racks 1.5 meters wide and 30 meters long.

The Spreadsheet Impact: You aren't handling units; you are handling bulk material. You fill a 50-ton room in 2 hours, close the door, and the machinery leaves. No moving parts stay in the room to be corroded by ammonia.

2. The Mushroom Blueprint: Master Your Airflow

Bob’s secret weapon is mushroom technology. Mushroom farmers have mastered the art of moving air through dense organic matter for decades.

The 9/10 Climate Rule

In a move that challenges "precision" ag-tech, Bob advocates for the 9/10 solution. A 10/10 system (like a fully aerated stainless steel wall) might be 4x the price of a 9/10 system (plastic air ducts).

- Airflow is Non-Negotiable: Whether you cool or heat is secondary. You must move air over every layer to vent the heat and ammonia generated by the larvae themselves.

- Insulation is Key: Bob uses specialized "poly-tunnels" with three layers of insulation. They aren't strawberry greenhouses; they are highly insulated, dark, permanent structures that are vastly cheaper than concrete warehouses.

3. The "Anti-Fluff" Spreadsheet: Technical Comparison

If you are an investor or a factory manager, these are the numbers that should change your financial model today.

| Metric | Automated Crate System | The Zoom Rack System | Spreadsheet Impact |

| Material Handling | Thousands of 60x40 units | Bulk handling (30m racks) | Labor Cost/Ton |

| Maintenance | High (Robotics in ammonia) | Low (Zero moving parts in room) | Annual OPEX % |

| Harvest Speed | Slow (Robot cycle time) | 50 Tons in 45 Minutes | Throughput Capacity |

| Yield Control | Static (No mid-cycle access) | Dynamic (Mid-cycle water/feed) | FCR & Final Yield |

| Work Schedule | Often 24/7 (Machine load) | Standard 8-hour workday | Labor Shift Premiums |

4. Mid-Cycle Flexibility: The Yield Protector

One of Bob's most disruptive engineering features is the ability to add water, feed, or mix the substrate after the room is closed.

In a crate system, if your batch starts to dry out or "crawl out," it's often a total loss. With a rack system, the farmer can walk in, see a dry top layer, and add moisture or fresh feed on Day 5.

"The larvae like it wet, but my sifter likes it dry. As an engineer, I shouldn't punish the larvae to make the sifting easier. I should fix the sifter." — Bob Holtermans

Hear the full podcast from David featuring Bob Holtermans

5. The Investor’s "No-B.S." Checklist

Bob’s advice for the next wave of BSF entrepreneurs is brutally honest. Before you pour concrete or buy a single rack, you must answer "Yes" to these three points:

- Do you have a locked-in customer? "Saving the world" is not a sales strategy. You need a contract for larvae or frass before you start.

- Is your feedstock consistent? BSF "eating anything" is a lab truth, but a commercial lie. You need predictable, high-volume raw materials.

- Are you focused on Farming or R&D? If you have 10 people in R&D and 1 in Sales, your priorities are flipped. Get the farm running at a constant production level first; research comes later.

The Bottom Line

The BSF industry is maturing. The era of "hype and hardware" is being replaced by "biology and bulk." As Bob Holtermans puts it: Keep it idiot-proof, handle it in bulk, and focus on the 8-hour workday.

If your current spreadsheet doesn't account for the corrosive reality of ammonia and the labor efficiency of bulk harvesting, it’s time to rethink your engineering.