In the world of sustainable protein, data is the new currency. Recently, industry leader Protix announced significant updates to their Life Cycle Assessment (LCA) for their Bergen op Zoom facility. While the detailed "White Paper" supporting these claims remains a "client-only" document, the public-facing science tells a story that the entire Black Soldier Fly (BSF) industry needs to hear.

At SoldierFlyHub, we believe that for this industry to scale, we must move beyond marketing highlights and look into the raw mechanics of sustainability. Below is our independent analysis of the new benchmarks.

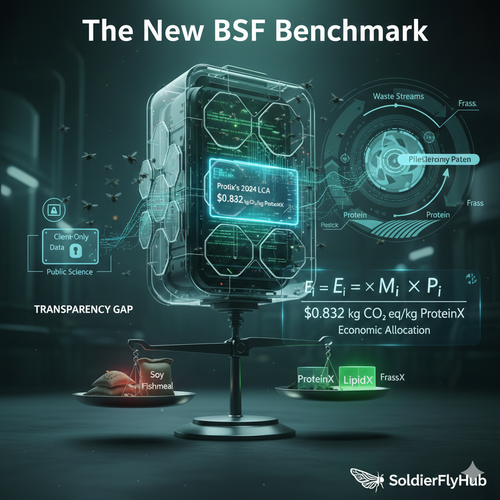

Executive Summary: The New Sustainability Floor

The 2024 data signals a shift from pilot-scale promises to commercial-scale reality. The key takeaway? BSF protein is now outperforming traditional benchmarks—like soy and fishmeal—not just in a lab, but in a massive, operational facility.

The Headlines:

- ProteinX (Meal): Footprint dropped to 0.832 kg CO2 eq/kg.

- LipidX (Fat): Footprint dropped to 0.47 kg CO2 eq/kg.

- Methodology: Protix has moved to Economic Allocation, the "Gold Standard" for global feed audits.

Why this matters: These numbers aren't just low; they are "audit-ready." By using Economic Allocation, Protix is ensuring their data can be used by global feed giants and ESG investors without the "marketing fluff" often found in smaller startups.

Technical Deep-Dive: The Mechanics of the 0.832 Benchmark

How did they get there? To understand the footprint of the meal, we have to look at how the environmental "burden" is calculated.

1. The Allocation Logic

Most BSF players use "Mass Allocation" (distributing emissions based on the weight of the output). Since frass is heavy, it "absorbs" the carbon footprint, making the protein look greener. Protix has opted for Economic Allocation (Eᵢ), which assigns the footprint based on the market value of the products:

$$E_{i} = \frac{M_{i} \times P_{i}}{\sum (M_{n} \times P_{n})}$$

By choosing this method, the high-value protein carries the majority of the facility's emissions. The fact that the footprint is still so low proves the efficiency of their heat recovery and genetic selection programs.

2. Substrate and The "Frass Factor"

The data highlights two primary levers of efficiency:

- Low-Burden Feed: By using industrial side-streams like gray starch and oat husks, the larvae start with a near-zero carbon debt.

- Frass Displacement: With a footprint of only 0.011 kg CO2 eq/kg, BSF frass acts as a carbon hero. When it replaces synthetic nitrogen fertilizer in the field, it creates a "displacement credit" that helps lower the overall facility footprint.

The SoldierFlyHub View: The Transparency Gap

While we applaud Protix for setting these benchmarks, their decision to keep the full technical White Paper behind a "client-only" gate highlights a growing challenge in our industry: The Transparency Gap.

The technical questions surrounding LCAs—such as specific substrate sensitivity and energy recovery ratios—are often dismissed as "too technical" for public consumption. However, at SoldierFlyHub, we believe these details are exactly what the industry needs to mature.

If we want the BSF industry to become a global standard, the "science" cannot be a trade secret. We will continue to analyze the peer-reviewed data and public filings to ensure our community has the facts, not just the press releases.